What are the 4 main types of Pedestrian Safety Barriers and Guardrails?

Incorporating pedestrian safety barriers and guardrails into the workplace is essential.

A visible safety barrier gives a clear indication and lessens the likelihood of accidents to employees and non-employees, and therefore creates a safer working environment.

The British Standards Institution (BSI) has published a publicly available specification for (PAS) 13, Code of Practice for safety barriers. Annually, the statistics show that more than 5,000 people are injured with approximately 50 people being critically injured or killed.

In this blog, we'll discuss four types of safety barriers, delve into PAS 13, and explore various warehouse safety barriers, including Pedestrian Safety Barriers, Polymer Safety Barriers, and Armco Safety Barriers.

Required Pedestrian Safety Barriers and Guardrails in the workplace

According to the Health and Safety Executive (HSE) the best practice for barriers should be:

• Located at the entrance of a car park or similar entrance.

• Established to allow people and vehicles to move safely in separate traffic routes.

• At the entrances and exits of buildings.

• At the corner of buildings.

• To prevent pedestrians from walking into roads and traffic routes.

These important applications of safety barriers can be segmented into 4 main categories: Pedestrian Safety Barriers, Traffic Management Barriers, Building Protection Barriers, and Access Control Barriers.

Pedestrian Safety Barriers and Guardrails

A pedestrian safety barrier and guardrail system will safeguard pedestrian traffic against workplace vehicles and hazards.

Pedestrian safety barriers are essential workplace safety installations designed to separate forklifts and other material handling equipment (MHE) from heavily trafficked pedestrian areas. Thus, ensuring the safety of employees and preventing accidents in industrial environments like warehouses.

This type of barrier should be used to separate pedestrians from hazards. For example, they can indicate that visitors are not permitted to walk across the MHE lanes. In the workplace, they provide protection for people from harm.

Pedestrian Safety Barriers and Guardrails are permanent, tested industrial or warehouse barriers, as opposed to cheap, non-permanent metal crowd control barricades or plastic road fences. For example, you could fit them to a mezzanine to protect employees from falling and injuring themselves.

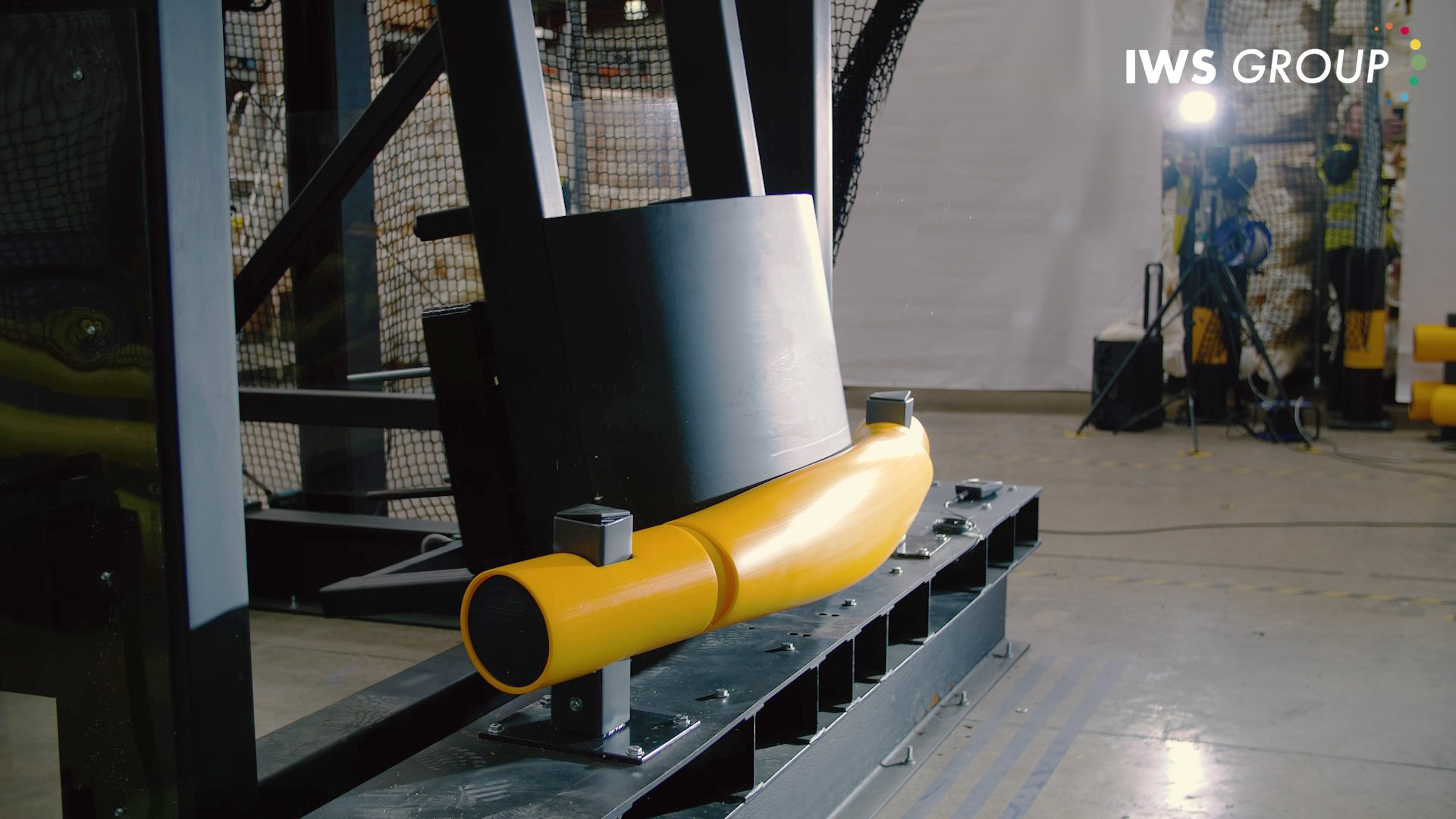

Moreover, the Guardrail Systems (MHE / PIT) are a perfect safety measure on the warehouse floor, protecting employees from forklift tines. As standard, it comes in high-visibility yellow, but custom options are available to suit various environments.

Additionally, if a simpler solution is required, then it would be best to install a Pedestrian Handrail System (HR50). A modular handrail system of galvanised steel covered with yellow and black polymer safety sleeves. This makes pedestrian routes stand out.

These handrails can also be attached to Armco Barriers for additional crash protection. The Armco 760HR Safety Barrier is another modular system with the ability to add any Armco accessories, for additional protection.

Traffic Management Barriers

Traffic safety barriers shield property and personnel against vehicle impacts.

These barriers should be used to act as a first line of defence against vehicular impacts. For example, the Armco Wall Mounted Safety Barrier is a great protective guard for load bearing walls, and walls directly in front of vehicle parking areas. In addition, they are equipped with rubber shock absorbers to act as a cushion on impact.

Made from galvanised steel it resists corrosion, while allowing some flexibility to deflect vehicular impacts.

Additionally, it should be noted that Armco is extremely versatile, being used inside warehouses as well as outside in HGV yards. Armco 1100D / 1100T Safety Barriers are a prime example of this as it can be easily double or triple stacked as required. This makes it ideal for storage picking areas and outside as a shield for pedestrians and structures alike. Its robust steel construction ensures long-lasting protection in high-traffic environments, and the reflective finish enhances visibility in low-light conditions.

Several reflective polymer Armco accessories can be attached to the barrier ends for higher visibility. For example, the Armco Safety End has two diamond grade reflectors and comes in either black or yellow colour options.

Finally, the outside walkways of facilities need to have separate traffic routes. Single Bumper Pedestrian Barriers are an excellent form of traffic partitioning.

Building Protection Barriers

Building protection barriers protect business assets from severe or repeated damage.

HSE highlights that the best practice is to align safety barriers where there is most likely to be a risk to personnel and/or property.

Suitable for many applications around a warehouse or factory floor. For example, Single Bumper Barriers are ideal by loading bay doors. Where pallets, stillages, and vehicular accidents are common. Typically, yellow finishes will be applied to increase general visibility and to warn of a hazard.

Furthermore, Double Bumper Safety Barriers are tested to deflect an Impact Energy of 14,200 J. These polymer safety barriers are a necessary safety feature for areas with repeated collisions. They will shield electric outlets, terminals, and loading bay door mechanisms.

We can consult with you to calculate the energy exerted in a collision based on your vehicle's maximum speed and weight, considering direct, 45-degree, and 15-degree impacts. Additionally, we can provide guidance on the optimal placement of speed restrictions, such as Speed Bumps.

Access Control Barriers

Access control barriers restrict and limit unauthorised access to restricted areas.

Simple solutions for this could be a Polymer Pedestrian Safety Barrier. Much like the Guardrail Systems (MHE / PIT) this has been engineered to deflect low tine forklift impacts and accidental MHE collisions.

The Pedestrian Safety Barrier is made from high density polyethylene (HDPE). This makes it non-toxic, and usable at operating temperature range of -40°C to 50°C. Ideal for food preparation and storage areas.

Furthermore, slowing or limiting the speed of foot traffic can reduce risk and improve safety compliance. For example, installing Pedestrian Safety Gates (made from HDPE) is an ideal accessory for a pedestrian crossing.

The Polymer Safety Barrier range is an excellent option for various production facilities as they are easy to clean and maintain. Available in a range of high visibility colours, contact us if you have any bespoke requirements.

Similarly, a different type of access control barrier could be Security Caging and Fencing. This method is to protect assets in a more protected and secure manner. For example, important resources such as gas, electric, or other control systems.

Standard colour options:

• Colourfast Yellow & Grey

• Hi-Vis Yellow & Blue

• Safety Yellow & Grey

Safety Barrier Colours - What do they mean?

Safety Barrier colours have significant cross-cultural universal meanings.

The following has been taken from a blog written by our sister company Beaverswood and the Health and Safety Executive:

Red

• Prohibited area

• Dangerous behaviour; stop; shutdown; evacuate.

Yellow / Amber

• Warning sign

• Be careful; take precautions; examine.

Blue

• Mandatory action

• Specific behaviour or action; wear protective equipment.

Green

• Emergency exit / First Aid station

• Doors; exits; escape routes; equipment and facilities.

Breaching these strict health and safety regulations is a criminal offence. Enforcement by the relevant authorities can result in serious fines or imprisonment as outlined by the Health and Safety Executive.

Action can be taken against companies, individual managers, and responsible persons.

Safety barriers and signs lessen the likelihood of accidents to employees and non-employees, and therefore creates a safer working environment.

(What are the 4 types of safety signs? Beaverswood, 2020).

Best Practices for Installing Your Pedestrian Safety Barriers

Installing your Pedestrian Safety Barriers and Guardrails is a significant process that ensures the safety of your workplace. Always consult your Health and Safety Specialist.

First, run a new risk assessment. Begin by assessing the areas where the barriers are needed, identifying high-traffic zones and potential hazards. Each business should use their specialists to determine the necessary area. It is important that the area chosen has sufficient room to support the stated deflection of a safety barrier. Otherwise, this would render the barrier ineffective. For example, the Double Bumper Pedestrian Barrier requires 232mm. Therefore, when it was tested to PAS 13 certification it flexed 232mm upon direct impact.

Subsequently, once you have determined the location, use the appropriate fixtures supplied to secure the barriers in place. It is the installers duty to ensure they are firmly anchored to withstand any potential impact. Make sure the barriers are positioned to create clear and easily navigable pedestrian walkways, separating them from vehicle traffic or hazardous equipment.

Finally, regularly inspect and maintain your barriers to ensure they remain effective in preventing accidents and protecting your employees.

By following these installation guidelines, you will enhance safety in your workplace. Creating a secure environment for both employees and visitors.

Alternatively, you can have them expertly installed by our Site Teams here at Brandsafe.

PAS 13 - Why it is important?

BSI released PAS 13, the safety barrier code of practice, to improve workplace safety by minimising accidents involving workplace transport. This collaborative standard offers guidelines on safety barrier impact resilience, dimensions, and positions. Emphasising the importance of implementing a safety traffic management system to safeguard personnel, vehicles, and structures in various workplaces.

It is one of the only specifications and standards for safety barriers in the workplace.

PAS 13 is crucial in the field of safety equipment. It is specifically aimed at products like Pedestrian Safety Barriers and Guardrails. This standardised testing procedure ensures that safety barriers meet stringent quality and performance standards, guaranteeing their effectiveness in real-world industrial environments.

PAS 13 provides several key benefits:

1. Quality assurance: PAS 13 testing ensures barrier strength through rigorous impact assessment.

2. Reliability: PAS 13 certifies barrier durability.

3. Compliance: PAS 13 aligns with safety standards.

4. Peace of mind: Certifications bring confidence.

5. Cost savings: Durable barriers save money.

In light of this, highlighting the importance of stringent testing, we have explored a few products from the Polymer Safety Barriers - PAS 13 Tested range. These barriers are proven to withstand high-impact collisions, ensuring robust safety in industrial settings. They are rigorously tested to PAS 13 standards, providing unmatched protection.

TÜV Nord

All our PAS 13 certified products are independently tested by TÜV Nord to PAS 13 standards. This means that an assessment is carried out by a member of TÜV Nord evaluating the production process, manufacturing, and installation of the barriers. Finally, testing their strength by simulating a high impact crash, which we carried out with the use of our custom built Pendulum.

Pedestrian Safety Barriers FAQs

What safety barriers are compulsory for workplaces in the UK?

In the UK, the requirement for safety barriers is governed by the Health and Safety at Work Act 1974, which mandates a safe workplace. The specifics depend on the workplace's individual circumstances and risk assessments. It's advisable to consult the Health and Safety Executive (HSE) guidelines or a health and safety professional to understand the exact requirements for your workplace.

What are pedestrian safety barriers and guardrails used for?

Pedestrian safety barriers and guardrails are used for separating all types of pedestrian foot traffic from any type of vehicular traffic. The main aim is to prevent loss of life or injury.

What does the colour of a safety barrier mean?

The most common safety barrier colour is yellow which indicates a warning of a hazard. Red safety barriers are used to highlight danger, prohibited areas, or to slow traffic down like a temporary road barrier. Finally, green safety barriers can be used to highlight safety routes to fire exists or first-aid.