Essential Steps for Choosing and Implementing Industrial Bollards for Safety Assurance

Industrial bollards play a crucial role in workplace safety by providing protection against vehicle collisions and creating safe spaces for employees and equipment. Whether you are looking to replace existing bollards or install new ones, it is essential to understand their importance and factors to consider before making a purchase decision.

Additionally, choosing the right supplier and following the correct installation process are vital to ensure bollard effectiveness. This guide will take you through all the necessary steps and considerations for buying and installing industrial bollards.

Discover everything you need to know about purchasing and installing industrial bollards for safeguarding your workplace in this comprehensive guide.

Understanding the Importance of Industrial Bollards

Industrial bollards play a crucial role in ensuring safety and security in various settings. These robust and sturdy vertical posts are specifically designed to prevent unauthorised access, protect buildings and equipment, and enhance pedestrian safety. With their durable construction and reliable functionality, industrial bollards have become an essential feature in many industries.

Defining Industrial Bollards

Industrial bollards are available in a wide range of materials, including steel, concrete, and plastic. This versatility allows them to withstand the harsh conditions often found in industrial environments. Steel bollards, for example, offer exceptional strength and durability, making them ideal for heavy-duty applications. On the other hand, concrete bollards provide a solid and immovable barrier, ensuring maximum protection. Plastic, otherwise known as polymer bollards, offer a combination of strength and versatility. They often have steel cores for strength but feature a polymer plastic shell that allows them to flex upon impact. Ultimately, this means polymer bollards will last longer than purely steel bollards, which can bend, or entirely concrete bollards, which can chip, crack, and crumble after severe impact.

These bollards come in various sizes, designs, and styles to suit different needs and preferences. From simple and functional designs to more aesthetically pleasing options, industrial bollards can be customised to blend seamlessly with the surrounding environment.

The Role of Bollards in Workplace Safety

One of the primary functions of industrial bollards is to act as both a visual and physical barrier, preventing vehicles from entering restricted areas. As a solution for this, we offer 3-meter versions of our ImpactSAFE Heavy Duty Bollard for extra visibility for high lorry and truck cabins. By clearly demarcating boundaries, bollards help minimise the risk of accidents and injuries in the workplace. This is particularly important in industrial settings where heavy machinery, forklifts, and other vehicles are often in operation.

Strategically placing bollards at key locations can create designated safe zones, ensuring that pedestrians and workers are protected from potential hazards. These safe zones can be established around entrances, loading docks, walkways, and other areas where there is a high risk of vehicle-related incidents. By effectively separating pedestrians from vehicular traffic, industrial bollards contribute to a safer and more organised work environment.

Example: Two Protection Bollards protecting a lift from heavy impacts.

Furthermore, industrial bollards help maintain smooth traffic flow within industrial facilities. By guiding vehicles along designated routes and preventing unauthorised access to certain areas, bollards ensure operations proceed efficiently and without disruptions. This not only improves productivity but also reduces the likelihood of accidents caused by congestion or confusion. We offer a light solution; Flexible Delineators that can demarcate different streams of traffic and snap back into place after being run over.

In addition to their practical benefits, industrial bollards can also enhance the overall appearance of industrial spaces. With the availability of different designs and finishes, bollards can be customised to complement the architectural style of the surrounding buildings. This not only adds aesthetic value but also creates a cohesive and visually appealing environment.

In conclusion, industrial bollards are essential elements in maintaining safety, security, and efficiency in various industrial settings. Their robust construction, versatile designs, and strategic placement contribute to the overall well-being of workers, pedestrians, and property. By understanding the importance of industrial bollards, businesses can make informed decisions to implement these vital safety measures.

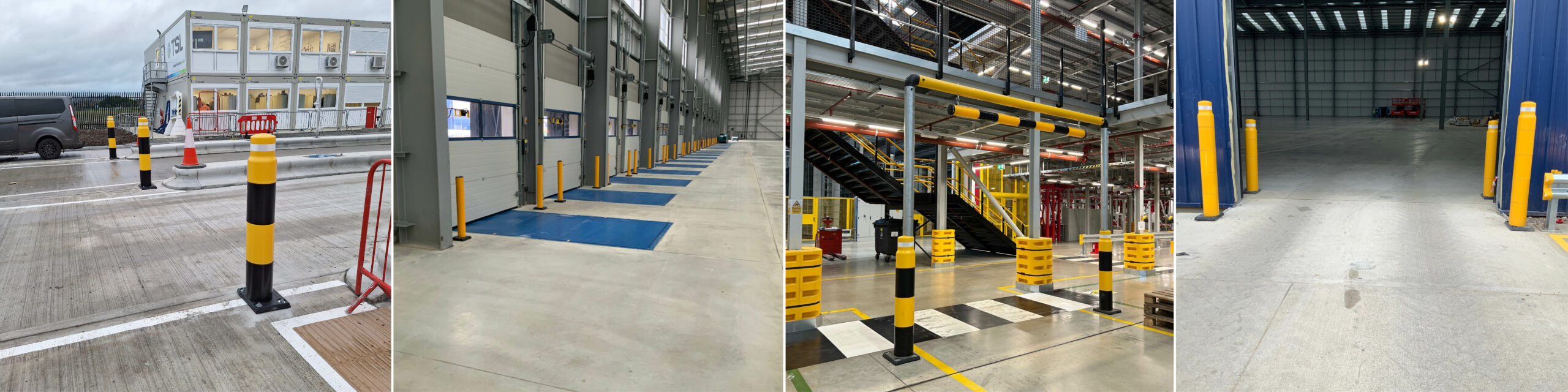

Yellow Heavy Duty ImpactSAFE, PAS 13 certified safety posts for enhanced workplace protection.

Factors to Consider When Buying Industrial Bollards

Industrial bollards play a crucial role in enhancing the safety and security of a workplace. Whether you need to protect pedestrians, control traffic flow, or safeguard valuable assets, choosing the right bollards is essential. When making this important decision, there are several factors to consider that will ensure you select the most suitable bollards for your specific needs.

PAS 13 tested Protection, EV Station potted and bolted Posts, Cover Kits for aesthetic enhancement, and Heavy-Duty solutions.

Material and Durability

One of the primary considerations when buying industrial bollards is the material used in their construction. The material significantly impacts their durability and longevity. Steel bollards, for example, offer superior strength and resistance, making them ideal for high-traffic areas or locations where vehicle impact is a concern. On the other hand, concrete bollards provide excellent impact resistance and are often used in areas where heavy machinery is present. Polymer bollards, crafted from durable plastic, blend robustness with flexibility. Their steel cores provide structural strength, while the polymer exterior grants the ability to flex when hit. This combination ensures a longer lifespan compared to solely steel bollards, which may warp, or concrete bollards, prone to chipping, cracking, and crumbling after intense impacts.

Furthermore, it is important to note that different materials may require different maintenance procedures. Steel bollards, for instance, may need periodic repainting to prevent corrosion, while concrete bollards may require occasional cleaning to maintain their appearance. Understanding the maintenance requirements of the chosen material is crucial for ensuring the longevity and effectiveness of the bollards.

Size and Design

The size and design of the bollards are also important factors to consider. The size will depend on their intended purpose and the surroundings in which they will be installed. For example, if you need bollards to control vehicle access, you may opt for taller and wider bollards to effectively deter unauthorised vehicles. On the other hand, if you require posts for pedestrian safety, shorter and more visible options may be more suitable.

In addition to size, the design of the bollards should also be taken into account. Consider factors such as visibility requirements and aesthetic appeal. Bollards that are highly visible can help prevent accidents and improve overall safety. Additionally, choosing bollards that blend well with the architectural style of your workplace can enhance the overall appearance of the area while still ensuring their functionality.

Furthermore, it’s crucial to look beyond to the broader spectrum of safety and operational efficiency within your workplace. Brandsafe offers an array of barrier solutions that cater to various aspects of workplace safety and functionality. From enhancing pedestrian walkways with our Polymer Safety Barriers to safeguarding storage areas and improving day-to-day operations with our Pedestrian Safety Barriers, each product is designed with the end-user in mind. Moreover, our Impact Protection Solutions provide an extra layer of security to both personnel and infrastructure, ensuring a comprehensive approach to workplace safety. When selecting safety barriers, consider the full range of options available to address the specific needs of your business, contributing to a safer, more efficient working environment. Explore our extensive product line to discover how Brandsafe can elevate safety and functionality at your facility.

Cost and Maintenance

Cost is another crucial consideration when selecting industrial bollards. While it may be tempting to opt for the most affordable option, it is important to weigh the initial cost against the long-term benefits. High-quality materials may have a higher upfront cost, but they often require less maintenance and offer a longer lifespan, resulting in cost savings over time. It is essential to consider your budget and balance it with the desired durability and performance of the bollards.

Furthermore, regular inspection and maintenance are crucial to ensure the continued effectiveness of the bollards. Developing a maintenance plan and adhering to it will help identify any potential issues early on and prevent costly repairs or replacements in the future. By investing in proper maintenance, you can extend the lifespan of the bollards and maximise their effectiveness in enhancing safety and security.

In conclusion, when buying industrial bollards, it is important to consider factors such as material and durability, size and design, as well as cost and maintenance. By carefully evaluating these factors, you can make an informed decision and select the most suitable bollards that meet your specific needs, ensuring the safety and security of your workplace.

Choosing the Right Bollard Supplier

When it comes to selecting a bollard supplier, there are several factors to consider that can greatly impact your overall experience and satisfaction. In addition to the basic criteria of reputation and experience, there are other important aspects that should not be overlooked.

ImpactSAFE Heavy Duty, ImpactSAFE Protection Posts, Goal Posts, Yellow Bollard Cover Kit.

Reputation and Experience

One of the first things to consider when choosing a bollard supplier is their reputation and experience in the industry. It is crucial to opt for manufacturers or suppliers who have a proven track record of delivering high-quality products and excellent customer service. This can be determined by checking online reviews and asking for recommendations from trusted sources. Check out our insightful case studies here.

Furthermore, a supplier with extensive experience in the industry is more likely to have a deep understanding of the various needs and requirements of different customers. They will have encountered a wide range of scenarios and challenges, allowing them to provide valuable insights and guidance throughout the purchasing process. With 14 years experience within the industry Brandsafe always strives to understand what the customer needs and deliver solutions that are tailored, effective, and reliable. Additionally, being part of the IWS Group, allows us to offer a complete comprehensive solution to warehouse and industrial requirements.

When selecting a bollard supplier, prioritise reputation and industry experience. A supplier with a strong track record in delivering quality products and exceptional customer service is essential. Online reviews and recommendations from trusted sources can provide insights into their reliability.

Moreover, seasoned suppliers are adept at navigating diverse customer needs and challenges, offering valuable insights and guidance. With 14 years of industry experience, Brandsafe exemplifies this expertise. We’re committed to understanding customer needs and delivering tailored, effective, and reliable solutions. As part of the IWS Group, we provide a comprehensive approach to warehouse and industrial safety requirements. Discover more about our commitment and solutions through our insightful case studies.

Product Range

Another important factor to consider is the supplier’s product range. It is essential to choose a supplier who offers a wide variety of bollard options to suit your specific needs. Whether you require removable, fixed, or retractable bollards, having a supplier who can provide the desired product variety is crucial.

Moreover, a diverse product range indicates that the supplier is well-equipped to cater to different industries and applications. This versatility can be particularly beneficial if you have unique requirements or if you anticipate the need for different types of bollards in the future.

Our comprehensive range:

- ImpactSAFE Bollards: PAS 13 Tested to 6100(J), ideal for heavy-duty protection in busy loading areas.

- Protection Bollards: PAS 13 Tested to 6000(J), sturdy solution for securing fire exits and critical site points.

- ImpactSAFE Protection Posts: Robust bollards for safeguarding EV stations and essential equipment.

- Drop Core Bollards: Demountable, embedded bollard for lasting impact resistance.

- Bollard Cover Kits: Instantly enhance old bollard aesthetics with protective polymer covers.

- Door Protection Goal Posts Systems: Shields upper areas of loading bays and low ceilings from damage.

- For custom solutions, please consult our Customer Solutions Team.

Customer Service and Support

Conclusion

In conclusion, industrial bollards are an integral part of workplace safety measures. Understanding their importance, considering factors such as material, size, and design, and choosing the right supplier are crucial steps in the buying process. Additionally, following the correct installation process and conducting post-installation checks are vital to ensure the effectiveness and longevity of the bollards. By following this ultimate guide, you can make informed decisions and create a safer work environment with industrial bollards.